Explore trends, tips, and tools

Blogs

6 Things Every New Car Owner Should Know (and Keep Handy)

10 Signs of PTSD After Car Accidents

Tired of fixing cars in that old garage? Remember this before you decide to renovate it.

How dangerous is white asbestos, and can it hurt your family? Experts Explain

The Healing Power of Stem Cells to Treat Vehicle Injuries

What Is a 2-Berth Motorhome?

Our Services

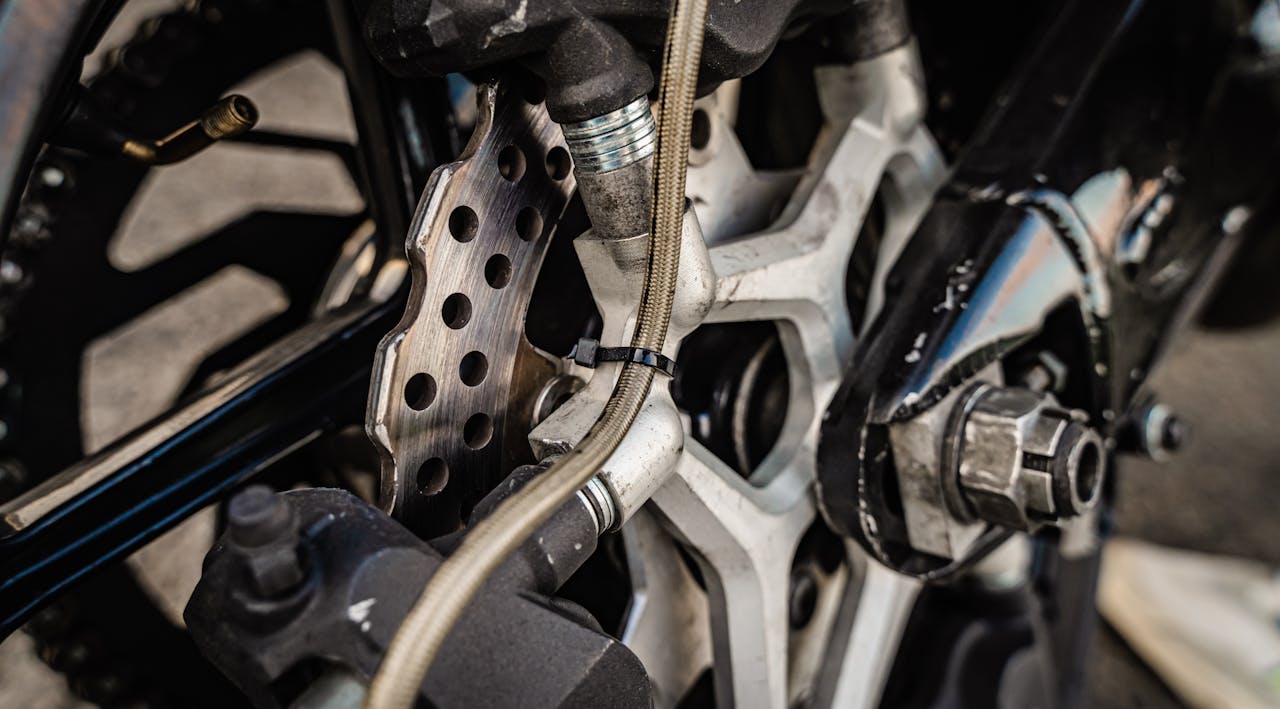

Comprehensive Brake Repairs and Servicing

01.

02.

03.

Get Your Brakes Checked Today

Contact us now for expert brake service and maintenance tailored to your foreign vehicle.

Our Process